This is an old revision of the document!

Table of Contents

Tubing

Before the the coming of carbon in 1990, all mountain bikes started their life as a box of metal tubes. Before Cannondale and Klein made aluminum commonplace in 1984, 99% of all MTBs were built from steel tubing1) from dozens of suppliers, from gas pipe to Reynolds. MTBs with a quality steel sticker were a cut above the rest, and probably a lot lighter as well. How important are these stickers, other than in dating the bike? A full materials science primer will follow, but for now, consider two bicycles:

- A 2024 Huffy Classic Deluxe, complete with fenders, basket, rack and a chain guard. Single speed.

- Weight: 47 → 52 pounds.

- Cost new today: $219.99.

- A 1938 René Herse touring bike, complete with fenders, bottle cage, pump, racks front and back, light and bell. 10 speeds.

- Weight: 17.50 pounds.

Have bicycles regressed? Is the metal in the Huffy that much denser? Solid iron, maybe? Did the unobtanium tubing used in the René Herse make it weaker than the Huffy?

Strong, Light, Cheap… Pick Two. Keith Bontrager

The René Herse was made of Reynolds 531 tubing, which debuted three years before, reducing some frame weights by nearly 50%. Double butting, tempering and careful blending of alloys can produce tubing which is 10x stronger then mild steel, allowing for Reynolds 531 frames to weigh 3.75 pounds, where some of the original MTB klunkers had frames over 20 pounds.

Any of the tubing manufacturers documented here make excellent tubing and any MTB with their decals is a cut above the heavy and weak gas-pipe bikes sold in certain department stores. So, is the best tubing simply what is strong and light? Well, yes…

Gary Fisher's converted 1942 Schwinn Excelsior still holds the Repack course record for a rigid bike. Weight: approximately 50 pounds. More info at: Charlie Kelley's website.

1947 René Herse, built with Reynolds 531 tubing. Since Reynolds 531 debuted in 1935, road bikes could often achieve weights under 18 pounds and remain reliable. The drillium saddle probably helped.

Overall resources:

Bundles of Ritchey Logic tubing waiting to be mitered and TIG welded.

ritcheyloggic

Reynolds tube sampler

reynoldstechnology

Columbus tubing on fresh frames at Mason Cycles.

base-mag

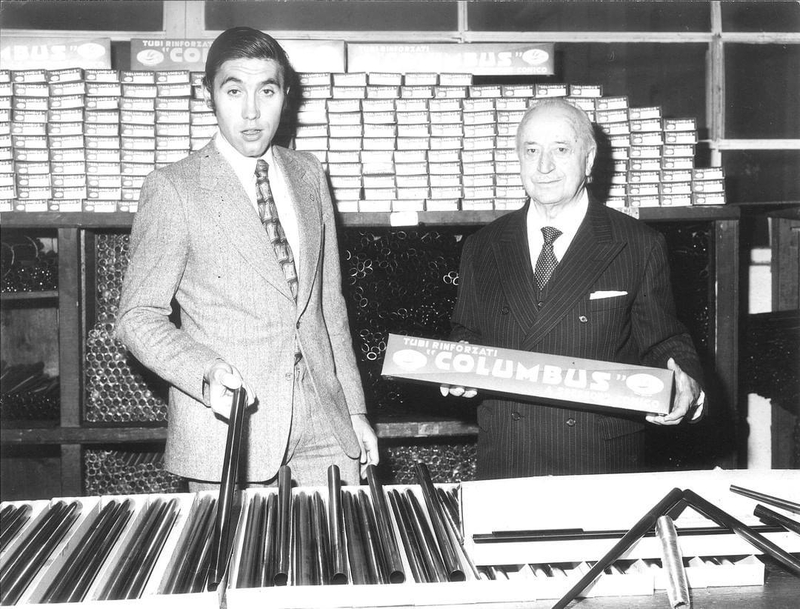

Angelo Luigi Colombo and the The Cannibal.

facebook

Tech Tutorial

The first Safety Bicycles of the 1880s weighed 42 pounds, with solid rubber tires and no gearing. The were built with steel tubing joined with soft iron castings. By 1897, before Reynolds double butted tubing, the safety bicycles were able to reduce their weight to as low as 22 pounds due to the creation of lighter and stronger steel alloys and pneumatic tyres. When Reynolds introduced the double butting process, it started a new era in lighter and stronger bicycles. By 1938 René Herse was producing touring bikes, complete with fenders, rack, light and bell weighing a feather light 17.50 pounds, built using thin Reynold 531 tubing.

Reynold 531 was an alloy of 98.1% Fe, 1.4% Mn, 0.30% C, and 0.20% Mo. How is this alloy composition its secret sauce? How is 531 better than other tubing? Does it better resist breaking or crimping? Is it easier to work with? More expensive? What do other manufacturers, such as Columbus use? What is strength anyway?

Stack of fresh Reynolds 953 tubing.

cyclist.co.uk

Material Strength: A Quick Primer

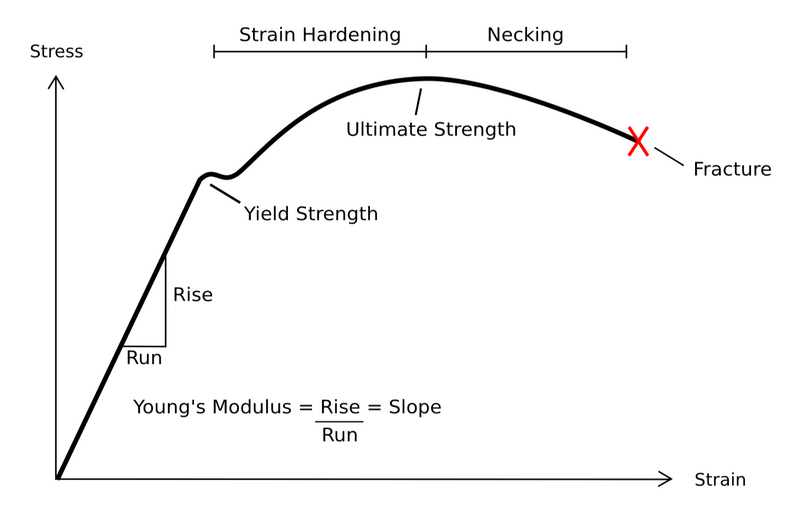

In the chart to the right –>

- stress := the amount of force3) applied.

- strain := the amount the material has deflected or bent.

- yield strength := the point where the bend becomes permanent or deformed. Think of bent tube becoming dented or creased.

- ultimate strength := the most stress a material can endure without breaking, aka “tensile strength” or “ultimate tensile strength.”

Bicycle owners should probably care more about yield strength instead of UTS (ultimate tensile strength), as a deformed tube is often thought of as a failed tube. Tubing manufacturers tend to publish UTS numbers, because they're much bigger. If the gap between the yield strength point and the fracture point is small, the material is considered to be brittle, such as glass. Else, it's elastic or ductile. For example, Reynolds 953 is 2.7 times stronger than Reynolds 531. Yet 531 is fairly elastic and is easier to repair than 953, such as by rolling tube blocks around the dent to squeeze it all back to shape 4). Young's modulus is how stiff the metal is: how much force it takes to bend5). Bending is related to fatigue limit, which is the point where bending starts to wear on the material. For steel, this is often about half the yield point. Steel can withstand an infinite6) amount of bending without wear until its bent near the fatigue limit. A well designed steel spring it will be springy until the end of time, or rusts claims it. Similarly, a well designed bicycle frame will never flex past its fatigue limit - which, of course, is very far from its yield and ultimate strengths.

Aluminum has no fatigue limit at all, so that any bending will degrade the material and cause it to fail, eventually. Typically, aluminum frames and components are overbuilt with this in mind to keep them alive for decades.

| Material | Yield Strength MPa | Tensile Strength MPa | Frame Weight 56cm |

| Cheep steel | 240 | 320 | |

| 4130 cold drawn | 482 | 655 | |

| Reynolds 525 (4130) | 600 | 700 | |

| Reynolds 531 | 695 | 803 | 2200 |

| Columbus Cromor | 700 | 750 | |

| Columbus SL, SP | 735 | 835 | |

| Columbus Niobium | 750 | 1150 | |

| Reynolds 725 | 880 | 1080 | |

| Reynolds 753 | 900 | 1100 | 1502 |

| Columbus Omnicrom | 920 | 1450 | |

| Columbus XCR | 950 | 1450 | |

| Reynolds 853 | 1000 | 1280 | |

| Reynolds 953 | 1900 | 2050 | 1300 |

| Carbon | N/A | 1600 | 1000 |

| Ti | 500 | 620 | 1542 |

| 6061 Al | 270 | 310 | 1700 |

Tech Resources:

Stress vs. Strain Curve

wikipedia

Densities

| Material | Density (g/cm3) | |

| Steel | 7.85 | |

| Titanium | 4.48 | |

| Aluminum | 2.7 | |

| Carbon | 1.75 | |